High accuracy is required when producing quartz capillary tubes for use in high-tech manufacturing industries. These tubes are employed in applications where accuracy and reliability are critical. In general, quartz capillaries also enhance the functionality of optical communication and electronics. When it comes to lasers or fiber optic connections, the choice of tube can positively influence the situation. Multiple hole configurations further improve the possibility of connectivity to enable precise data transfer.

Applications of Quartz Capillary Tubes in Optical Communication

Due to their low aging effect, Quartz Capillary Tube is a significant aspect of Optical communication systems. It supports different devices, including the PLC splitter access ends, fiber optic connectors, sensors, and the WDM wavelength division multiplexers. These components play a significant role in maintaining effective signal flow. Quartz capillary tubes contain multi-holed facilities and, therefore, high flexibility when it comes to the connection can easily be made with high accuracy. This will enhance the stability of the signal as well as reduce the chances of transmission errors, especially in industries that deal with large amounts of data.

Besides optical communication, these tubes are also used in other fields, such as medical and electronics. Whether its application is in the medical field, in diagnosis equipment, or in electronics, the accuracy provided by these capillary tubes enhances the device’s functionality.

Multi-Hole Quartz Capillary Tubes for Advanced Devices

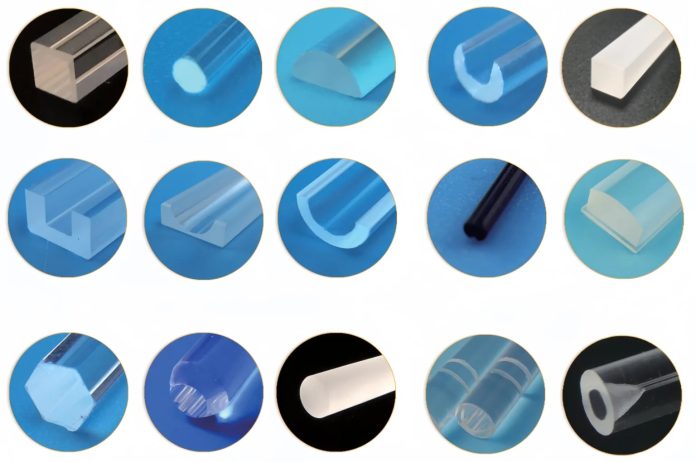

Multi-hole quartz capillary tubes can be made in several shapes, including elliptical, square, rectangular, triangular, and eccentric. The holes are provided so that more requirements of various devices can be fitted in. And with acceptable positional inaccuracies of ±0.03mm, it can be possible to be assured that these tubes will serve the highest demand of any company or facility.

For example, the multi-hole configuration in fiber optic systems allows for more connection points without affecting signal quality. Customization possibilities also assist in adapting these tubes for specific devices, improving performance.

For those who require capillary tubes for a few highly specialized kinds of equipment, these custom tubes offer the proper amount of flexibility to integrate with the various systems without modification. For instance, a device that requires more than one fiber optic connection finds this feature very suitable because it increases the number of holes, thus, the data an organization or a business entity is processing or receiving, making the work run fast and efficiently.

Various Shapes and Materials for Versatile Applications

Different forms of Quartz capillary tubes include the conical, D-shaped, elliptical, trapezoidal, and hexagonal forms. The form of this tube depends on its application, and every type holds special features for the devices in use. Others enable better fitting and integration into highly technological devices. Moreover, the variety of materials used adds to the flexibility of these tubes even more. There are quartz glass or borosilicate glass among them, which also has its advantages, such as density or thermal stability.

Because these tubes can be made from various materials, they are appropriate for numerous industries. For instance, a suitable material improves the efficacy of energy transmission in the laser industry. These tubes are also beneficial in the medical field, especially for devices that need precise and accurate flexibility.

Custom Solutions for Specific Industry Requirements

The specification of sectors that will require capillary tubes could be met by tubing with specific characteristics tailored to the tasks at hand. For example, if you are designing a new generation of optical sensors, a specially tailored tube will enhance device performance. The presence of such options makes it possible for industries to address the diverse requirements of equipment.

It also guarantees that tubes adhere to the high demands of the technology being worked on. Adjusting the tube’s shape, size, or material implies a level of flexibility that satisfies the requirements of one industry or another. Due to technological growth, high-accuracy requirements such as quartz capillary tubes are needed, and such customized optoelectronic solutions enable developments in such areas.

Conclusion

Quartz capillary tubes with high accuracy are vital in enabling most modern technologies. These tubes fit perfectly in optical communication, medical devices or electronics; they provide the level of accuracy and stability needed to thrive. Multi-hole configurations, shapes, and the choice of materials provide the needed design characteristics for more advanced devices. Quartz capillary tubes remain vital in today’s advanced technological society because of their emphasis on quality and customization in a number of industries.