Which 4-Axis CNC Machine Applications Are There?

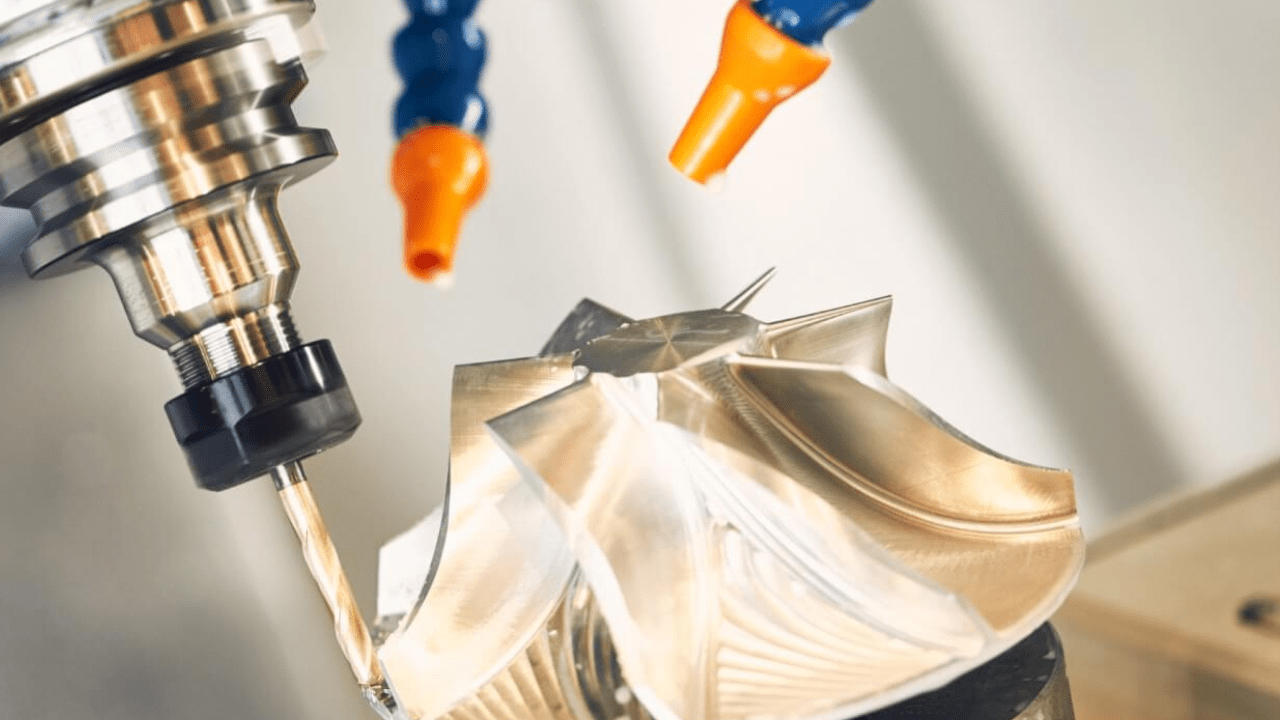

4-dimensional A further rotational axis, referred to as the A-axis, is introduced in CNC machining, an advanced manufacturing technique, to expand the capabilities of the standard 3-axis CNC. The fourth axis, which allows the cutting tool to rotate around the workpiece and facilitates machining from different angles, is in addition to the conventional X, Y, and Z axes for linear movements.

The machine can now create intricate and complex parts with more precision thanks to this extra dimension. The utilization of 4-Axis machining is beneficial for the production of complex components in a variety of industries that demand precise geometries, shorter setup times, and enhanced productivity.

Which Sectors Gain from Four-Axis CNC Machining?

Many industries that require precise and complex components use 4-axis CNC machining. Its capabilities are used by aerospace manufacturers for intricate aircraft parts and by the automotive industry for complex engine components. Manufacturers of medical devices profit from their accuracy in creating complex prosthetics and implants. It is used in the field of art and design to sculpt and create intricate decorative elements. Furthermore, for rapid iteration in prototyping, 4-axis CNC machining is essential.

Application of 4-Axis CNC Machine

Four-axis CNC machines sometimes referred to as four-axis machining centers, supplement conventional three-axis CNC machines with an extra rotational axis. More flexibility is offered by this additional axis, which also permits more intricate machining tasks. Typical uses for 4-axis CNC machines include the following:

Improved 3D Machining Accuracy:

The exceptional precision with which 4-axis CNC machines can execute complex 3D machining tasks is one of their main advantages. These machines are equipped with a rotary axis in addition to the conventional X, Y, and Z axes. This allows the cutting tool to access various sides and angles of the workpiece. In fields like aerospace, where complicated components with intricate geometries are frequently used, this capability is especially advantageous.

Manufacturing of Intricate Models:

4-axis Prototyping is a common use for CNC machines in product development. They can manipulate the workpiece in various directions, which enables the creation of complex and intricate prototypes. This is important for sectors like the medical and automotive industries, where accurate and thorough prototypes are necessary for testing and validation before mass production.

Efficient Production of Mold and Die Components:

Four-axis CNC machines are essential for the production of molds and dies. Complex shapes and contours can be machined thanks to the rotary axis, which is useful when producing molds and dies. The time and labor required to create molds for plastic injection or die-casting processes are greatly decreased by this capability.

Increased Production Efficiency for Aerospace Components:

The complex shapes and profiles that are frequently needed for aerospace components call for a high degree of precision during manufacturing. For these kinds of applications, 4-axis CNC machines are ideal since they can produce complex aerospace components more quickly and efficiently with less setup time. The machine’s ability to precisely cut, shape, and drill materials like titanium and aluminum is beneficial to the aerospace industry.

Detailed engraving and ornamental work:

Four-axis CNC machines are very adaptable in the engraving and ornamental work industries. These devices are capable of precisely engraving complex patterns on a variety of materials, such as plastic, metal, and wood. This makes them indispensable in fields like jewelry making, where precise designs and complex patterns are frequently needed.

Cost-Effective Batch Production:

4-axis CNC machines provide affordable solutions for industries that produce components in batches. Time and money are saved because fewer setups are required when the workpiece can be manipulated from various angles. This is especially helpful for sectors like electronics, where it’s typical to produce intricate parts in big quantities.

Bottom Lines

4-dimensional with the ability to facilitate accurate and effective manufacturing processes, CNC machines have become essential assets for many industries. Their adaptability in handling difficult jobs has revolutionized production, from intricate artwork to aerospace components. These devices are set to take on an even more significant role as technology develops, helping to continuously improve manufacturing capacities.