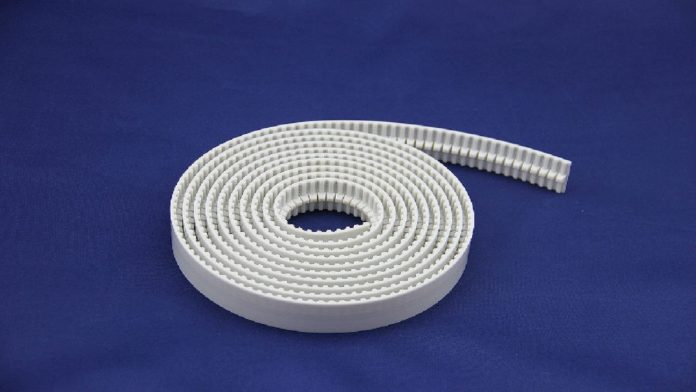

Timing belts are found in several mechanical applications; they solve the power transmission problem and act as a synchronization component. Of all the timing belts, open-ended timing belts produced from extruded thermoplastic polyurethane (PU) are one of the best in the market due to their exceptional performance. These belts provide the main advantages that make many linear drive systems prefer them. In this article, the benefits that come with the use of an Open Timing Belt will be discussed, as well as the factors that have led to increased demand for the belt.

Better Dimensional Stability

The important benefit of the open-ended timing belt is better dimensional accuracy. Made from extruded thermoplastic polyurethane, it is intended to maintain its shape and size regardless of the surrounding climate. This makes it possible to achieve repeatable and accurate positioning in linear drives, making it suitable for operations where accuracy is paramount. It can be applied in operations such as robotics, packaging machines, or industries and, therefore, assists the system’s precise enhancement.

Resistance and Endurance to Harsh Conditions

There is also the following advantage to applying open-ended timing belts: these belts are incredibly durable. The construction of these belts allows them to handle extraneous operating conditions easily. They are supported by tension cords located alongside the edges of the belt to add strength and stability. Furthermore, open-ended timing belts manufactured by reputed brands like ZZR have numerous kinds of resistance; they are used to withstand wear and abrasion, cuts, and mechanical damage. This product’s durability implies a long service duration, meaning owners will not need to service or replace the products frequently.

Improved Resistant to Chemicals and Environment

Open-ended timing belts manufactured from thermoplastic polyurethane display various abilities to withstand differing environmental and chemical effects. These belts also offer good resistance to acids, bases, oils, and fats and are suitable for handling such products in industries. Moreover, these belts are resistant to fire due to the chemicals used in manufacturing them, and they have become useful to systems that portray a high risk of fire. This immunity to external influences increases the belts’ durability and power-bearing capacity, which is why they are used in many industries.

Precision and Efficiency in Linear Drive Systems

Open-ended timing belts are favored by industries that require precise linear motion transmissions and are independent of power trains. The extruded thermoplastic polyurethane construction allows the belts fabricated from it to maintain their shape and elasticity under tension and when used for a long period. Because of their ability to position belts with high accuracy, they are ideal in systems that call for systems to move in harmony, for example, in robotics, automation, and packaging. Through proper adjustment and transport of the parts, these belts minimize mistakes, increase the systems’ operational effectiveness, and raise the equipment’s general performance.

Conclusion

In conclusion, using extruded thermally activated polyurethane timing belts with open-ended structures provides these advantages in dimension stability, durability, and ability to withstand adverse conditions. Due to their orientation retention and functionality in harsh conditions, they are indispensable to contemporary linear drive arrangements. In any application, such as robotics, industrial machinery, or packaging systems, these belts have become an efficient solution that has made many applications successful in different industries.